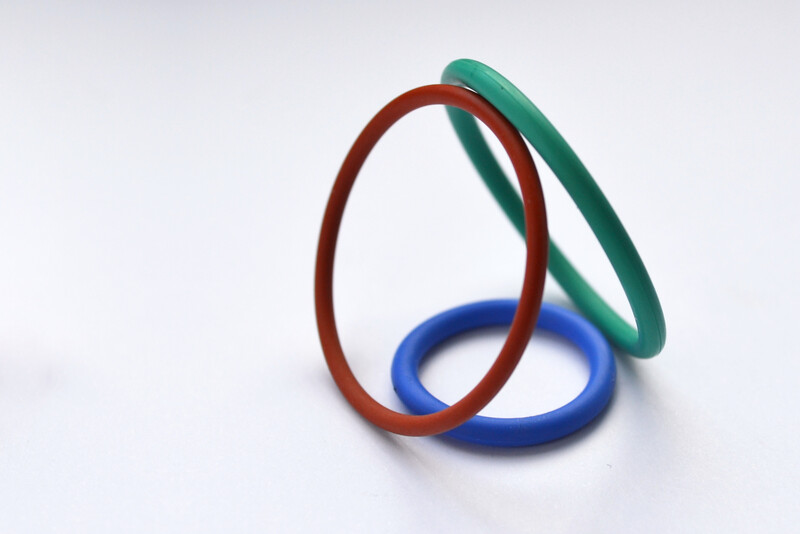

Silicone - high-performance elastomers for every area

Quickfacts Silicone

Application

Materials

MVQ, VMQ, PVMQ, PMQ, FMQ, FVMQ

Variations

Hardness

Manufacture

Colors

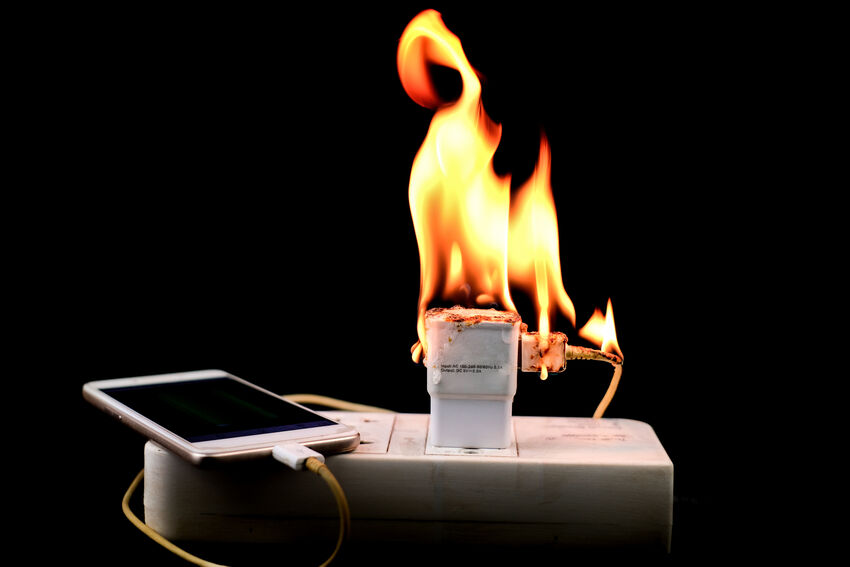

| Application | Sealing, insulating, damping (e.g. battery technology), transportation of media, etc. |

| Materials | MVQ, VMQ, PVMQ, PMQ, FMQ, FVMQ |

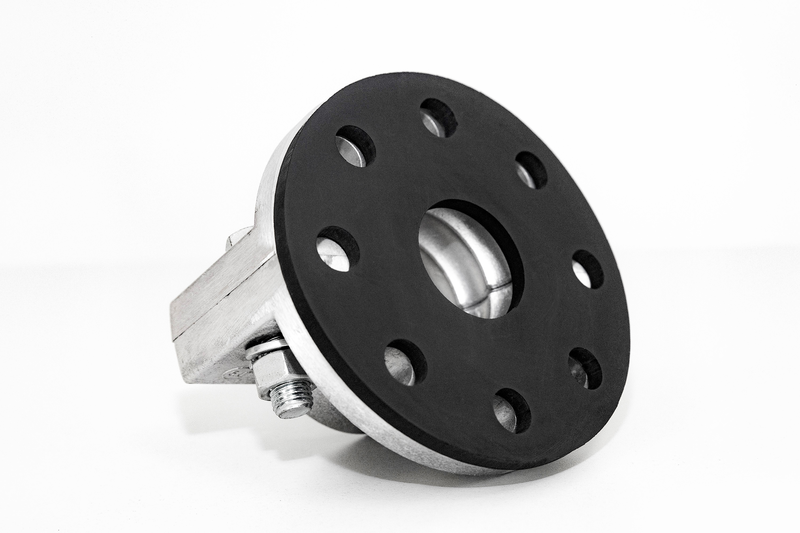

| Variations | Molded parts (LSR and HTV silicone), extruded products, sheet goods, stamped parts in solid and foam silicone |

| Hardness | 20 ± 5 Shore A to 90 ± 5 Shore A |

| Manufacture | Depending on the product: LSR (liquid silicone rubber), HTV (high-temperature vulcanizing), extrusion, calendering, punching, plotting, water jet cutting |

| Colors | Customized according to RAL color, transparent possible |

Request a free sample now

Further details in the catalog

Request a free sample now

Automotive

Mechanical engineering

Food industry

Medicine and pharmaceuticals

Aerospace and mass transit

Renewables, Energy Storage, Big Data and Semiconductor

Jäger Gummi und Kunststoff and our sister companies Jäger Precision Elastomers and Jäger Polska have various in-house production capacities in the field of silicone molded parts, as well as the production and assembly of profiles, hoses and stamped parts. From rudimentary work such as cutting to length and gluing to the fully automated assembly of a 3K part made of plastic, metal and LSR silicones.

As a European distributor of high-performance silicone foams from Futureway©, we can offer our customers access to an outstanding material that is used worldwide in state-of-the-art automotive applications (battery technology) and in the semiconductor industry (stack production).

Our product and process development team will be happy to advise you on the implementation of your drawing articles or the planning of new projects in order to subsequently realize the optimal production of your desired silicone product.

Whether in-house production or through our partners, the customer receives the best solution.

Solid silicones are rubber-like products that are manufactured as sheet goods, extrusions (hose or profile geometry) or molded parts. The compounds used range from a Shore hardness of 10° Shore A to 90° Shore A. The density of the materials ranges from approx. 1.1g/cm³ to 1.3g/cm³ depending on the additives, filling materials and type added. Depending on the mixture, measurable values such as elasticity, compression set or tear propagation resistance can change accordingly or be specifically adjusted.

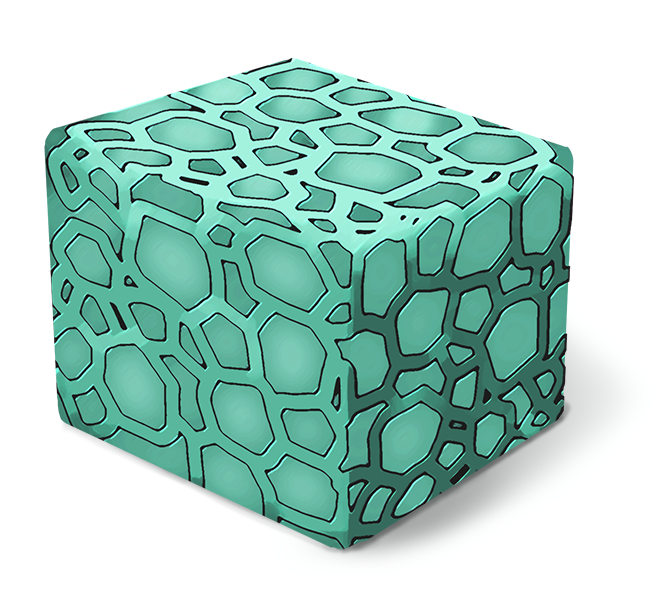

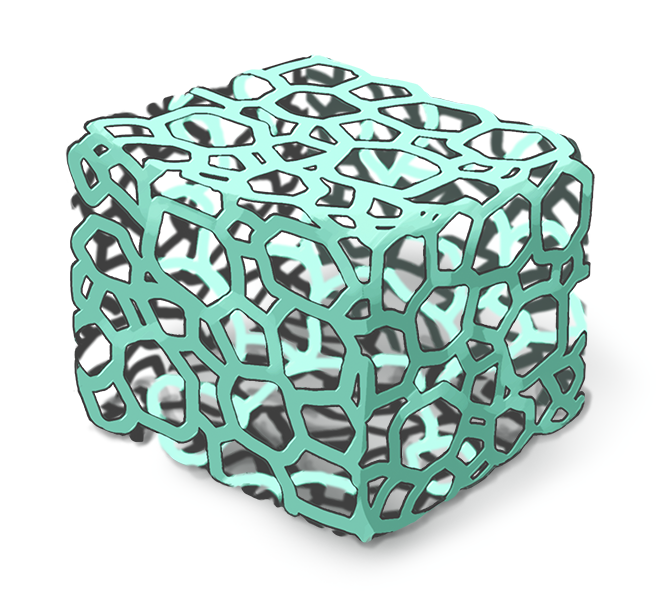

Additional chemical reactions in the material make it possible to foam silicone. This reduces the density of the material and creates air pockets in the material. The densities usually range from 0.2g/cm³ to 0.8g/cm³. Depending on the type of reaction, so-called “closed-cell” or “open-cell” structures are created. Apart from the fact that the materials are significantly lighter, they are also easier to press due to the gas inclusions. The chambers in the material created by the reaction ensure a significantly lower thermal conductivity, which makes silicone foams an excellent insulator. Silicone foams are also indispensable as vibration dampers or sealing materials in batteries, airplanes or passenger vehicles.

Blog

Discover exciting content in our blog posts

19. Oktober 2022

Fire protection is an important topic in the plastics and rubber sector. In particular, companies should be familiar with the two standards UL94 and DIN EN45545.

28. September 2022

Brandschutz ist ein wichtiges Thema im Kunststoff- und Gummibereich. Insbesondere die beiden Normen UL94 und DIN EN45545 sollten Unternehmen kennen.

31. August 2022

02. Februar 2022

Whether metal or plastic – particularly strict requirements apply to materials in the food sector. Find out more on the Jäger blog!

15. September 2021

The choice of sealing material has a great influence on the service life of a machine or plant. Do not only pay attention to the price!

03. November 2021

In sealing technology, it is essential to know the practical framework conditions- from application temperature to legal requirements.

01. September 2021

Rubber production is an energy-intensive process. Therefore, you should already proceed intelligently and methodically with the material selection.

Jäger Gummi und Kunststoff GmbH

Lohweg 1

30559 Hannover

Tel. +49 511 – 53580

Fax +49 511 – 553394

info@jaeger-gk.de

Management:

Dr.-Ing. Andreas Jäger und

Julius Jäger

Hanover Register Court HRB 59798

DE 813 314 161