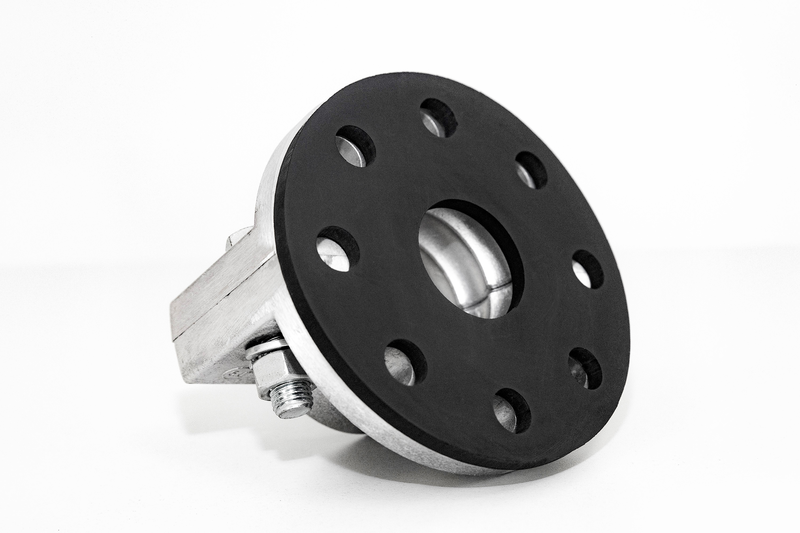

Innovative design meets functionality: focus on molded plastic parts

Quick facts plastic molded parts

Application

Materials

PA, POM, PET, PC, PPE, PVC, PE, PP, PEEK, PPS, PSU, PUR, TPE, ABS, PC/ABS, PBT, …

Manufacture

Injection molding, blow molding, foaming, thermoforming

Max. Injection weight (in-house production)

Max. Locking force (in-house production)

Quantity

Colors

RAL colors

| Application | Insulating, decorating, connecting, stiffening, etc. |

| Materials | PA, POM, PET, PC, PPE, PVC, PE, PP, PEEK, PPS, PSU, PUR, TPE, ABS, PC/ABS, PBT, ... |

| Manufacture | Injection molding, blow molding, foaming, thermoforming |

| Max. Injection weight (in-house production) | up to 2,000 g |

| Max. Locking force (in-house production) | up to 450 t |

| Quantity | on request |

| Colors | RAL colors |

Request a free sample now

Further details in the catalog

Request a free sample now

Storage of additional components

Simultaneous development

Blog

Rubber production is an energy-intensive process. Therefore, you should already proceed intelligently and methodically with the material selection.

Blog

Whether metal or plastic – particularly strict requirements apply to materials in the food sector. Find out more on the Jäger blog!

Blog

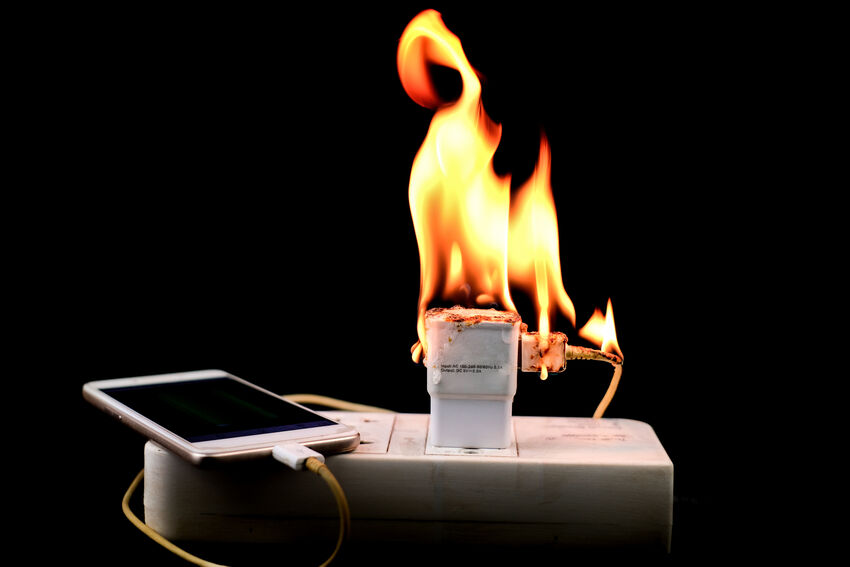

Fire protection is an important topic in the plastics and rubber sector. In particular, companies should be familiar with the two standards UL94 and DIN EN45545.

Blog

In sealing technology, it is essential to know the practical framework conditions- from application temperature to legal requirements.

Jäger Gummi und Kunststoff GmbH

Lohweg 1

30559 Hannover

Tel. +49 511 – 53580

Fax +49 511 – 553394

info@jaeger-gk.de

Management:

Dr.-Ing. Andreas Jäger und

Julius Jäger

Hanover Register Court HRB 59798

DE 813 314 161