A prerequisite for a successful sustainability strategy is a detailed knowledge base. Therefore, we first investigated which business units consume how much energy. In the course of this, we were able to identify six major energy consumption groups:

This analysis formed the basis for determining our energy baseline – a comparison of inputs, broken down into energy sources, and outputs, i.e., energy consumption per point of use. The primary energy sources or types of energy used by Jäger are natural gas, heating oil and electricity. This compares to the following consumption points at Artemis:

Based on our analysis, we were able to calculate the energy consumption as well as the CO2 emissions per kilogram of rubber mass processed. We took the result as the actual state as well as a key figure to evaluate the effectiveness of our improvement measures.

Based on the consumption analyses, we identified and implemented a number of optimization measures. Some of these were technical in nature, while others related more to organizational factors.

Our first optimization measure was to change the energy source. In the past, Jäger obtained thermal energy mainly from crude oil. In the meantime, we have largely switched to natural gas, which has significantly lower CO2 emissions.

In parallel, we have refurbished our lighting. Instead of HQL lights, we now use LED lamps exclusively. Some of these are equipped with daylight sensors that reduce energy consumption to the bare minimum. As a result, we were able to reduce energy consumption for lighting by 70 percent.

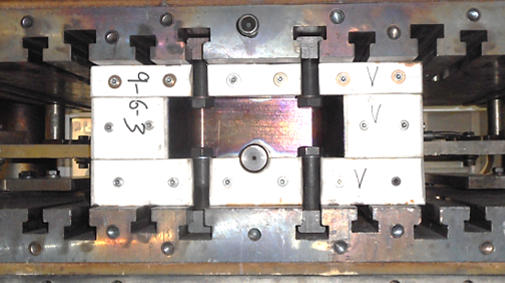

Next, we addressed the issue of mold insulation and thermal insulation. To this end, we fitted the majority of our injection molding molds with insulating layers and improved the insulation on the machine side so that the molds no longer emit heat to the machine frame. Combined, these measures have reduced energy consumption per square meter of mold by 1.4 kW.

The drive and control technology was also the subject of our optimization measures. For example, our injection molding systems now no longer use conventional hydraulic motors and pumps, but a combination of smaller servomotors that can all be addressed individually in the interests of demand-oriented servohydraulics.

Where possible, we have retrofitted frequency converters and used more energy-efficient drives. According to an internal directive, new motors must not be worse than IE3.

We have equipped our existing plants with phase-angle controllers that briefly throttle the machine’s output during low-load or no-load phases, thereby reducing energy consumption. This is particularly relevant during long heating phases and resulted in energy savings of around 10 percent.

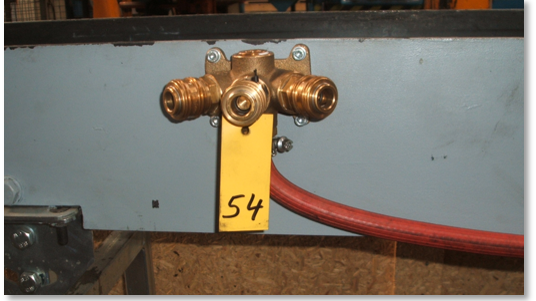

A major issue was and still is the systematic review of weak points. We examined all our machines and systems to see if energy was being lost somewhere. This included possible compressed air leaks, weak points in insulation areas, and a check of steam fittings using sound measurement. The identified leaks or damage were then eliminated by our maintenance department. This is a continuous process that we always continue.

At the organizational level, we have above all created a cross-departmental awareness of energy-efficient working. We now have an interdisciplinary energy team comprising representatives from all energy-relevant areas as well as the management. This team meets regularly to discuss optimization potential and possible improvement measures. We have also established a company suggestion scheme that enables employees to submit ideas for saving energy.

With the help of the measures described, we succeeded in saving more than 2,000 tons of CO2 between 2012 and 2020. In addition, we were able to reduce energy consumption per kilogram of rubber produced by 20 percent in the same period.

As a result, we are not only making our contribution to combating climate change, but also reducing our energy costs on top of that – an advantage that we also pass on to our customers. For example, we are less affected by price fluctuations on the energy markets and therefore do not have to pass on rising costs in full to our customers.

Rebecca Goetze studied industrial engineering at Leibniz University in Hanover with a focus on production technology and has been strategic head of purchasing at Artemis since 2019. In parallel, she has also been the company’s energy management officer since 2012.