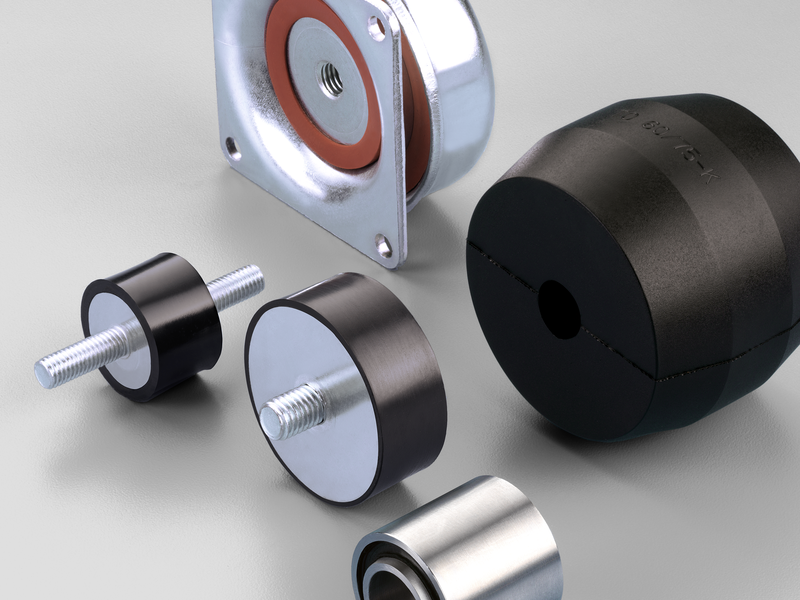

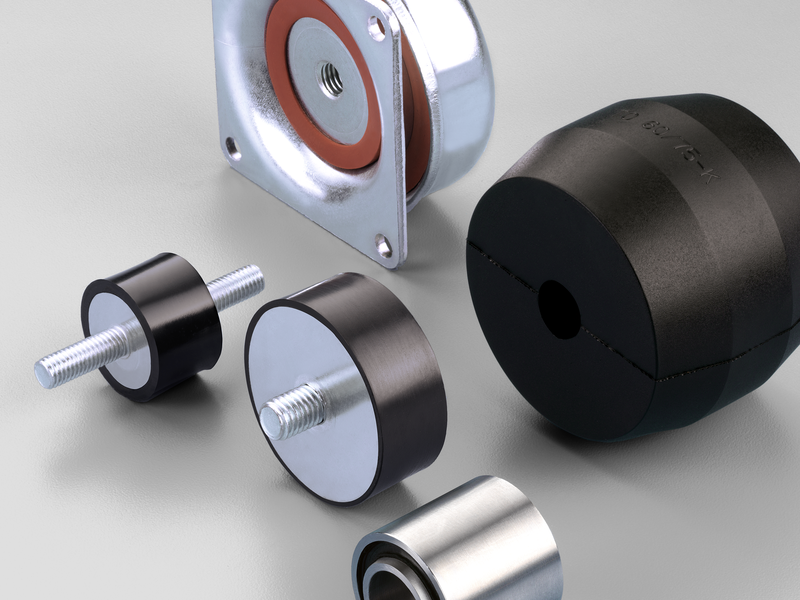

Material combinations for demanding applications

Rubber-metal elements are essential for vibration damping and noise reduction. They are used in the automotive industry, mechanical engineering and construction to extend the service life of components and increase comfort. Jäger supplies clutch buffers, friction wheels, bearing elements, spring and damping elements, bushings, valve balls, piston bodies, stators, disk springs or shaft bearings, machine feet and other rubber buffers. Standardized or specially adapted to your requirements.

Quickfacts Rubber-Metal Elements

Application

Storage, decoupling, damping

Materials

NR, IIR but also e.g. EPDM, NBR, silicone, etc.

Hardness

soft (approx. 40-45 ±5 Shore A), medium (approx. 50-55 ±5 Shore A), hard (approx. 65 -70 ±5 Shore A)

Quality

Megi® & Schwingmetall®, but also alternative qualities

Standard rubber-metal buffer

Versions: A, B, C, D, E – further versions e.g. AT = “waisted”, AP = “parabolic”, K = “conical”, S = “with bead”

Further products

Ring buffers, conical bearings, rubber-metal rails, stop rails, U-rails, machine feet (height-adjustable, with or without breakaway protection), torsion bushings, rubber-metal hat elements, hydromounts, rubber-metal bushings, pot elements, etc.

Color

Standard: black, other colors on request

| Application | Storage, decoupling, damping |

| Materials | NR, IIR but also e.g. EPDM, NBR, silicone, etc. |

| Hardness | soft (approx. 40-45 ±5 Shore A), medium (approx. 50-55 ±5 Shore A), hard (approx. 65 -70 ±5 Shore A) |

| Quality | Megi® & Schwingmetall®, but also alternative qualities |

| Standard rubber-metal buffer | Versions: A, B, C, D, E - further versions e.g. AT = "waisted", AP = "parabolic", K = "conical", S = "with bead" |

| Further products | Ring buffers, conical bearings, rubber-metal rails, stop rails, U-rails, machine feet (height-adjustable, with or without breakaway protection), torsion bushings, rubber-metal hat elements, hydromounts, rubber-metal bushings, pot elements, etc. |

| Color | Standard: black, other colors on request |

Request a free sample now

Further details in the catalog

Request a free sample now

Our rubber-metal elements offer an innovative solution for technical systems with high sealing requirements. Where space is at a premium, conventional seals make assembly difficult. We vulcanize seals directly onto metal components in the injection moulding process, which creates a reliable, tool-bound connection. This offers significant advantages in sealing performance compared to freely applied seals.

For example:

Further products

Case Study

Blog

Blog

Blog

Jäger Gummi und Kunststoff GmbH

Lohweg 1

30559 Hannover

Tel. +49 511 – 53580

Fax +49 511 – 553394

info@jaeger-gk.de

Management:

Dr.-Ing. Andreas Jäger und

Julius Jäger

Hanover Register Court HRB 59798

DE 813 314 161